#compression tooling

Explore tagged Tumblr posts

Text

Carbon Fiber and Composite Materials: A New Era for Heavy-Load Railway Freight Cars

The Role of Carbon Fiber Composite Materials in Modern Rail Transportation

Jointly developed by the China Energy Group’s Railway Equipment Company, the Beijing Low-Carbon Clean Energy Research Institute, and CRRC Qiqihar Rolling Stock Co., Ltd., these railway freight cars not only represent a leap forward in the application of new materials but also contribute to green, low-carbon rail transportation solutions.

Lightweight and Intelligent Design for Energy Efficiency

Under the guidance of national strategies like "Strengthening Transportation" and "Dual Carbon," there is a growing demand for the green transformation of the transportation sector. The China Energy Group, managing over 57,000 railway freight cars, plays a key role in transitioning toward energy-efficient, lightweight solutions for large-scale freight operations, particularly in coal transport.

The new carbon fiber composite railway freight cars are a significant advancement in lightweight, high-strength, and low-energy solutions. These cars are a direct result of integrating compression molding technology and advanced composite materials, setting new benchmarks for efficiency and sustainability.

Advantages of Carbon Fiber Composite Materials

1. Higher Strength-to-Weight Ratio

Compared to traditional materials, carbon fiber composites offer a strength-to-weight ratio 3-5 times higher than aluminum alloys, making them ideal for heavy-load railway freight cars. This higher ratio allows for reduced vehicle weight without compromising structural integrity.

2. Reduced Weight for Increased Efficiency

The carbon fiber composite body reduces the weight of the railway freight cars by more than 20% compared to similar aluminum vehicles. This significant weight reduction, with a self-weight coefficient as low as 0.22, allows for greater load capacity and improves overall transportation efficiency.

3. Enhanced Durability and Environmental Resistance

Technological Innovations in Heavy-Load Freight Cars

1. Optimized Bogies and Air Brake Systems

The new cars are equipped with optimized K6-type bogies, which enhance load distribution and stability. Integrated air brake systems ensure efficient braking, further improving the cars' safety and control.

2. Smart Monitoring Systems for Real-Time Data Collection

These freight cars incorporate smart monitoring systems powered by IoT, big data, and cloud computing, enabling real-time data collection on the performance of the cars. This system improves predictive maintenance and helps optimize energy consumption, contributing to greener transportation solutions.

Compression Molding: A Key Manufacturing Technique

The use of compression molding for carbon fiber composite materials has been instrumental in the development of these new railway freight cars. Compression molding allows for the efficient production of large, complex parts with precision, making it ideal for large-scale components such as the car bodies.

Advantages of Compression Molding for Carbon Fiber Components

High precision and consistency in part production.

Efficient manufacturing of large parts in a single operation.

Minimized material waste, especially important with high-cost materials like carbon fiber.

Conclusion: Pioneering the Future of Green Rail Transport

The successful development of carbon fiber composite heavy-load railway freight cars signals a major step forward in the future of rail transportation. With the combined benefits of lightweight design, improved durability, and cutting-edge technologies like smart monitoring systems, these cars offer revolutionary advantages for green, low-carbon transport.

As global transportation continues to evolve, the integration of composite materials and compression molding technology will remain pivotal in shaping the next generation of heavy-load railway freight equipment.

#compression tooling#compression mold#smc mold#bmc mold#smc tooling#bmc tooling#composite mold#compression molding

2 notes

·

View notes

Text

I gave up at the end, Procreate Dreams is frustrating as hell lol I haven't animated in a long time either

#its not terrible for putting it together in a night#definitely gonna try other software if i wanna animate stuff tho#this bitch dont even got a lasso tool#resus community#resus#cpr#chest compressions#female resus#defibrillation#ambu bag#my art

192 notes

·

View notes

Text

talkin bout friends and pals

#ive been having fun with animation but GOD it takes forever#at least in aseprite. which is my animation tool of choice#also the compression on this gif is kinda shitty and i hate it but whatevs#hilda's art landfill#madotsuki#yume nikki#poniko#the batter off#zacharie off#off game#space funeral#phillip space funeral#leg horse space funeral#leg horse#rpg maker#animation#lots of tags im sorry

506 notes

·

View notes

Text

A grumpy lil Izzy for all your grumpy Izzy needs! put him in whatever situation you want :) (NO JARS)

#someone take the lasso tool away from me#i jst thought this one really was perfect to just. stick him in images#also obsessed with his stupid lil ties. theyre so obnoxious here. his thighhhhh. HIS THIGH#nyxtalks#ofmd#our flag means death#izzy hands#israel hands#transparent#as ever: im makin these for fun but feel free to use him if u want! take my guy on an adventure#if you want the original quality one just drop me a message! i had to compress this to high hell to get tumblr to take it#even though this started out smaller than the last one did#but its a known issue apparently :/

118 notes

·

View notes

Text

Because I was curious to know what was in the other side of spearmaster's gate

#I used a lot of dev tools I know#I just wanted to satiate my curiosity#rw#rain world#rw spearmaster#(I don't know if I'm allowed to use the spearmaster tag)#I compressed this SEVEN FUCKING TIMES AGGHHHHH

10 notes

·

View notes

Text

contractually obligated annual canyon drawing

#compression murdered my boy#why did i insist upon using pixel tool instead of a real brush again#doomonart#codename corbeau#it's janky but it's finished so whatever

4 notes

·

View notes

Text

Behold, a bitchy oc

If I had the transparent jpeg of him I would post it down here, but I don't lol.

The best part of having an oc oc is now I can insert him into anything!

#monster prom oc#oc#my art#my artwork#my oc art#I finally learned how to use a layered photoshop image like a normal person instead of just abusing the fill tool#do not ask me about his shoes#I tried my absolute hardest to match MP's artstyle but I think I still failed to capture it's distinct angularness#oh well#also why is my artwork so compressed???

2 notes

·

View notes

Text

How Much Does a Compression Mold Cost?

Compression molding is a widely used manufacturing process, particularly for thermosetting plastics, which involves the shaping of material through heat and pressure. As businesses explore this method for producing high-quality parts, understanding the costs associated with compression molds becomes essential. This article will delve into the factors influencing compression mold pricing, the average costs, and tips for managing these expenses effectively.

Factors Influencing Compression Mold Costs

1. Material Selection

The type of material used for the mold significantly impacts its cost. Common materials for compression molds include aluminum and steel, with steel being more durable and typically more expensive. The specific requirements of the part being produced, including its size and complexity, will also dictate material choices.

2. Mold Complexity

3. Size of the Mold

The size of the mold correlates directly with its cost. Larger molds require more material and machining time, which can lead to higher overall expenses. For instance, a small, single-cavity mold might cost around $5,000, whereas a large, multi-cavity mold could cost $50,000 or more.

4. Production Volume

The anticipated production volume plays a significant role in mold cost justification. For high-volume production runs, investing in a more expensive mold may be cost-effective in the long run due to lower per-part costs. Conversely, for small production runs, businesses may opt for less expensive molds, even if they sacrifice durability or efficiency.

5. Lead Time

The lead time required for mold creation can also affect costs. Rushed projects typically incur premium charges due to expedited services. Standard lead times can range from a few weeks to several months, depending on the complexity and current workload of the manufacturing facility.

Average Costs of Compression Molds

On average, the cost of compression molds can range significantly based on the factors discussed:

Simple Single-Cavity Molds: $3,000 - $10,000

Moderately Complex Molds (Multi-Cavity): $10,000 - $50,000

Highly Complex or Large Molds: $50,000 - $150,000+

Tips for Managing Compression Mold Costs

1. Design Optimization

Investing time in optimizing the mold design can lead to significant cost savings. Simplifying the design while ensuring functionality can reduce material and machining costs.

2. Consider Long-Term Needs

Evaluate the long-term production needs. While a higher initial investment may seem daunting, the overall cost per unit can decrease with larger production volumes, making it a more economical choice.

3. Supplier Selection

Choose a reputable mold manufacturer with a track record of quality and reliability. Established suppliers may offer better pricing due to their experience and efficiency in production processes.

4. Regular Maintenance

Conclusion

Understanding the costs associated with compression molds is crucial for businesses looking to leverage this manufacturing process. By considering the various factors that influence mold pricing—such as material selection, complexity, size, and production volume—companies can make informed decisions that align with their budget and production goals. Implementing strategies for cost management can further enhance the financial viability of using compression molds in manufacturing. For businesses aiming to produce high-quality, durable parts, investing in the right compression mold is not just a cost—it's a valuable asset for future growth.

#compression tooling#compression mold#smc mold#bmc mold#bmc tooling#smc tooling#composite mold#compression molding#money

0 notes

Text

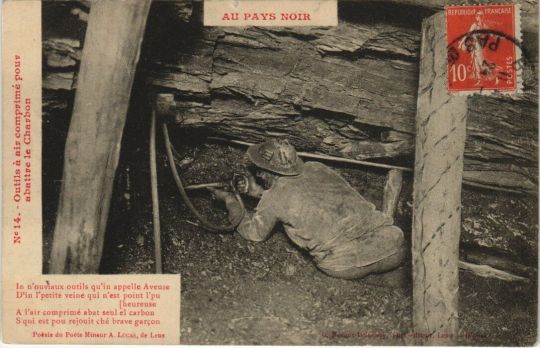

Compressed air tools in coal mining, French Hainaut region of northern France

French vintage postcard, mailed in 1911

#vintage#photography#compressed#postkarte#french#carte postale#mining#air#postal#region#briefkaart#tools#france#postcard#old#photo#coal#ansichtskarte#sepia#1911#postkaart#ephemera#mailed#tarjeta#hainaut#northern#historic

10 notes

·

View notes

Text

im doing so many studies rn, im gonna level up so hard with my art (<- said through gritted teeth and a forced grin)

#skull and hand and general body anatomy proportions so far#I feel my brain expanding (/silly)#I've just noticed i keep drawing ppl way too compressed/condensed so all the limbs end up too short sjdjdkl#so I have to go back to basics to figure out where I've gone wrong#and the skull studies are bc i cannot for the life of me figure out how to place the nose and mouth and chin lately#i seem to end up with too low of noses and mouths and not enough chin djdksl and its esp noticeable on side profiles#and the hand studies... well. we all know how hands are tools of the devil and therefore cannot be drawn easily SBSBDHDHJSL#GRRRR IM GONNA GET THIS ALL FIGURED OUT THOUGH IM MAKING GOOD PROGRESS#I'm working on body proportions rn dhdksl giving me a lot of trouble though bc ppl are not all built the same#dandy.cmd

5 notes

·

View notes

Text

Socket Plug connectors, Receptacle Housing, cable connectors

DT Series Contact Size 16 3 Way Gray Receptacle Housing

#TE Connectivity#DT04-3P#Connectors#Tooling and Accessories#Cable compression tool#SAN#cable crimper#Tin Plated Contacts#f connector#Socket Plug connectors#Receptacle Housing#cable#Crimp Contact Socket#Ethernet crimping

2 notes

·

View notes

Text

The Ultimate Guide to Top Recovery Boot Systems for Enhanced Performance

Recovery boot systems have revolutionized the way athletes and fitness enthusiasts recover from intense workouts. These innovative devices utilize compression therapy to enhance circulation, reduce muscle soreness, and expedite the recovery process. When it comes to maximizing performance and maintaining peak condition, investing in top-quality recovery boot systems is essential. The advanced…

#athletic recovery#compression therapy#fitness gear#muscle recovery#performance enhancement#recovery boots#recovery equipment#recovery technology#recovery tools#sports performance

0 notes

Text

Tablet Tooling Manufacturer - Tablet Punches & Dies | IRM Enterprise Pvt. Ltd

The quality of Tablet Compression Tools directly affects the uniformity, performance, and appearance of pharmaceutical tablets. For this reason, manufacturers rely heavily on the expertise of a trusted Tablet Tooling Manufacturer. At IRM Enterprise Pvt. Ltd, we specialize in crafting high-precision Tablet Punches and Dies, helping pharmaceutical companies achieve superior quality and maximum production efficiency.

As a leading Tablet Tooling Manufacturer, we understand that every client requires tools that meet exacting specifications and industry standards. Our wide range of Tablet Press Tooling includes standard and Custom Tablet Tooling, engineered to support smooth, consistent operation across all types of Tablet Compression Machines. Whether you need tooling for standard shapes or specialized designs, IRM Enterprise Pvt. Ltd delivers excellence in every component.

What is Tablet Tooling?

Tablet Tooling refers to the Tablet Punches and Dies used in Tablet Compression Machines to compress powder formulations into solid pharmaceutical tablets. Each tooling set generally consists of two punches (upper and lower) and a die. The precise dimensions and tolerances of these components ensure that the tablets produced are uniform in size, shape, weight, and appearance.

Tablet tooling plays a crucial role in pharmaceutical manufacturing, impacting product quality, production efficiency, and regulatory compliance. Investing in High-Quality Tablet Press Tools helps manufacturers avoid common issues such as tablet sticking, capping, lamination, or weight variation.

Tablet Tooling Solutions from IRM Enterprise Pvt. Ltd

As a specialized Tablet Tooling Manufacturer, IRM Enterprise Pvt. Ltd offers a complete range of tooling products, including:

Tablet Punches Manufacturer

Tablet Die Manufacturer

Tablet Compression Machine Tooling

Custom Tablet Tooling

Precision Tablet Tooling

Tablet Press Parts Manufacturer

Our product line is designed to meet the needs of modern pharmaceutical companies, nutraceutical brands, and industrial tablet producers. Whether you require standard tooling for round tablets or customized punches for branded shapes, we provide solutions that ensure optimum performance and longevity.

Key Features of Our Tablet Tooling

IRM Enterprise Pvt. Ltd’s Tablet Compression Tools stand apart for their:

Precision Manufacturing: Each punch and die is produced with the highest levels of accuracy to meet tight tolerances.

High-Quality Materials: We use hardened tool steel and premium coatings to enhance wear resistance and corrosion protection.

Smooth Surface Finish: Polished surfaces ensure minimal friction, reducing sticking and increasing tool life.

Custom Designs: We specialize in Custom Tablet Tooling to accommodate a variety of tablet shapes, logos, and special requirements.

Consistency & Reliability: Our tools deliver consistent results even under high-volume production.

Interchangeability: Compatible with all major tablet press brands and models.

Regulatory Compliance: Our tooling meets international standards for the pharmaceutical industry.

Applications of Tablet Press Tooling

Our Pharmaceutical Tablet Tooling is used in various industries and applications:

Pharmaceutical Manufacturing: Producing tablets for prescription medications and over-the-counter drugs.

Nutraceutical & Dietary Supplements: Manufacturing vitamin tablets, mineral supplements, and herbal products.

Confectionery Industry: Forming candies and mints into consistent shapes and sizes.

Industrial Tablet Production: For producing tablets in sectors such as detergent manufacturing, battery components, and more.

Benefits of Using High-Quality Tablet Tooling

Investing in premium Tablet Compression Tools from IRM Enterprise Pvt. Ltd provides numerous benefits:

Improved Tablet Quality: Uniform shape, size, and weight with clean edges and professional appearance.

Increased Production Efficiency: Faster cycle times with reduced downtime.

Extended Tool Life: High wear resistance and durability reduce the need for frequent replacements.

Reduced Manufacturing Costs: Improved performance minimizes waste and rejects.

Regulatory Compliance: Helps manufacturers meet GMP and quality control requirements.

Why Choose IRM Enterprise Pvt. Ltd as Your Tablet Tooling Manufacturer?

When selecting a Tablet Tooling Manufacturer, quality, expertise, and service make all the difference. Here’s why IRM Enterprise Pvt. Ltd is trusted by pharmaceutical companies worldwide:

Decades of Experience: With years of industry experience, we understand the unique challenges faced by pharmaceutical manufacturers. Our technical team collaborates closely with clients to develop the best Tablet Press Tooling solutions.

Advanced Manufacturing Capabilities: We operate a state-of-the-art manufacturing facility with precision CNC machining, advanced grinding equipment, and rigorous quality control processes. Every punch and die is inspected for dimensional accuracy and surface finish.

Custom Tablet Tooling Expertise: Our team excels in producing Custom Tablet Tooling, from embossed logos to complex tablet geometries. We help our clients create distinctive tablet designs that enhance brand recognition.

Commitment to Quality: Every set of Tablet Punches and Dies we produce adheres to the highest quality standards. We use certified materials, advanced coatings, and proven processes to deliver tools that exceed expectations.

Superior Customer Support: We are more than just a Tablet Press Parts Manufacturer—we are your partner in tablet production success. Our team provides technical assistance, tool maintenance guidance, and responsive customer service.

Our Range of Tablet Tooling Products

At IRM Enterprise Pvt. Ltd, we supply a broad array of Tablet Compression Tools, including:

B & D Tooling

Compatible with rotary presses, ideal for medium- and high-volume production.

BB & DB Tooling

Suitable for compact tablets and multi-tip tooling.

Multi-Tip Tooling

Allows simultaneous production of multiple tablets with each machine cycle, increasing output.

Customized Punches & Dies

Tailored to client specifications—shapes, sizes, logos, and special coatings.

Spare Parts & Accessories

Complete range of Tablet Press Parts to support ongoing operations and maintenance.

Precision Tablet Tooling for Modern Pharma Needs

Today’s pharmaceutical companies face growing demand for innovative, attractive, and effective tablets. Our Precision Tablet Tooling helps manufacturers achieve:

Distinctive branding through custom logos and tablet designs.

Superior mouthfeel and swallowability with consistent tablet shapes.

Enhanced shelf appeal with clean, defect-free finishes.

Consistent tablet weight for accurate dosing.

Compliance with GMP and quality control standards.

By partnering with IRM Enterprise Pvt. Ltd, clients gain access to superior Pharmaceutical Tablet Tooling that meets the evolving needs of global markets.

In an industry where quality, performance, and regulatory compliance are critical, choosing the right Tablet Tooling Manufacturer is key. IRM Enterprise Pvt. Ltd is proud to be a leading supplier of Tablet Punches and Dies, Custom Tablet Tooling, and High-Quality Tablet Press Tools for pharmaceutical and industrial applications.

Whether you require standard tooling for routine production or advanced Precision Tablet Tooling for complex formulations, we are here to help you achieve excellence in every tablet you produce.

Looking for a Trusted Tablet Tooling Manufacturer?

Contact IRM Enterprise Pvt. Ltd today to discuss your Tablet Press Tooling requirements and discover how our expertise can help you optimize your tablet production processes!

For more info: https://www.karnavatiengineering.com/

Call Now: 7567876473

Email id: [email protected]

Location: S. No. 342, Nani Kadi, Taluka - Kadi, Dist - Mehsana, Gujarat - 382715, India

#Tablet Tooling Manufacturer#Tablet Compression Tools#Tablet Punches and Dies#Pharma Tablet Tooling#Tablet Press Tooling Supplier#Custom Tablet Tooling#High-Quality Tablet Press Tools#Tablet Press Parts Manufacturer#Pharmaceutical Tablet Tooling#Tablet Punches Manufacturer#Tablet Die Manufacturer#Tablet Compression Machine Tooling#Precision Tablet Tooling

0 notes

Text

What are the Characteristics of Compression Molding Molds?

Compression molding is a high-efficiency, cost-effective method for producing complex parts using composite materials. The molds used in this process—known as compression molds—are essential in ensuring quality, strength, and durability of the finished product. This article explores the main characteristics of compression molding molds, including their structure, materials, applications, and unique advantages.

1. Precision and Customization in Mold Design

Compression molding molds offer customization for various applications, such as automotive and industrial panels. They support:

Custom Part Geometry: Tailored molds for complex shapes.

Tolerance Control: Ensures precise part dimensions and reduces material waste.

2. Materials for Compression Molding Molds

Compression molds are usually made from robust materials capable of withstanding high pressures and temperatures:

Steel: Ideal for high-cycle durability.

Aluminum: Great for lower-volume runs due to its thermal conductivity.

Beryllium Copper: Used for intricate details and high thermal conductivity.

3. Mold Structure and Key Components

Key structural elements of compression molding molds include:

Cavity and Core: Define the product shape.

Heating System: Ensures material curing.

Ejector System: Facilitates part release.

Guiding System: Aligns mold halves for accuracy.

4. High Heat Resistance and Stability

Compression molds must withstand high temperatures for material curing, with features such as:

Heat Resistance: Withstands up to 300°F or higher.

Dimensional Stability: Retains shape under high temperatures and pressure.

Even Heat Distribution: Reduces cycle times and ensures quality.

5. Durability and Longevity

Compression molds are designed for durability, often lasting thousands of cycles:

Material Choice: High-quality steel and alloys enhance longevity.

Surface Treatment: Chrome plating for wear resistance.

Cycle Efficiency: Reduced wear compared to other mold types.

6. Cycle Time Efficiency

Efficient cycle times are essential for compression molding. Factors enhancing efficiency include:

Quick Heat Transfer: High thermal conductivity materials reduce heating time.

Optimized Part Release: Smooth finishes and ejector mechanisms minimize sticking.

7. Compatibility with Composite Materials

Compression molds are compatible with a variety of composite materials like SMC, BMC, and thermosets:

Material Flow: Even distribution for defect-free parts.

Material Curing: Even curing for strength and durability.

8. Applications Across Diverse Industries

Compression molds are widely used in industries including automotive, aerospace, and electrical:

Automotive: Panels, body parts, and interior components.

Electrical: Insulators and housings with precise tolerances.

Household Products: Durable components for daily use.

9. Cost-Effectiveness and Efficiency

Compression molding offers a cost-effective solution for medium to high-volume production:

Low Material Waste: Pre-measured charges minimize excess material.

Low Tooling Costs: Compared to injection molding.

Simplified Setup: Reduces operational costs.

10. Design Flexibility and Enhanced Surface Finish

Compression molding molds offer flexibility and high-quality finishes:

Texture and Pattern Integration: Custom finishes for aesthetic appeal.

High-Quality Surface Finish: Smooth results, reducing post-processing needs.

Minimal Draft Angles: More precise part geometries.

Conclusion

The characteristics of compression molding molds—durability, precision, and compatibility with composite materials—make them essential for high-quality production in diverse industries. These qualities not only ensure product durability but also optimize production efficiency. By understanding these characteristics, manufacturers can make informed decisions, improving product outcomes and achieving cost-effective, reliable manufacturing solutions.

#compression tooling#compression mold#smc mold#bmc mold#bmc tooling#smc tooling#composite mold#compression molding

0 notes

Text

FFmpeg: The Ultimate Tool for Multimedia Processing

FFmpeg is a powerful open-source tool for handling multimedia files. Whether you’re encoding, decoding, converting, or streaming, FFmpeg is widely used for manipulating video and audio. Getting Started FFmpeg can be installed on various operating systems: Windows: Download from the official site. Here Mac: Use Homebrew: Brew install ffmpeg Linux: Install via package managers like APT or YUM: sudo…

#Audio Editing#Command Line Tools#Encoding & Decoding#FFmpeg#Linux#macOS#Media Conversion#Multimedia Processing#Open Source Software#Streaming#Tech Tools#Video Compression#Video Editing#windows

0 notes

Text

Caesium Image Compressor: Free & Efficient Image Optimization

Caesium Image Compressor is a fast, free, and safe image compression tool that works seamlessly across platforms, including Windows, Mac, and even Android. Ideal for photographers, bloggers, and web developers, it allows you to optimize image files without sacrificing visual quality. Whether you’re compressing images for faster website loading, saving disk space, or preparing files for online…

#batch image compressor#Caesium image compressor Android#Caesium image compressor for Windows 7#Caesium image compressor free#Caesium image compressor online#image compression tool

0 notes